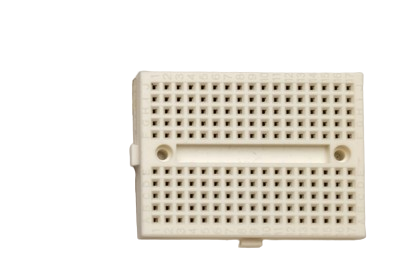

Bread-Board Mini Circuit Board

₨120.00

Delivered All over Pakistan 🇵🇰

A Breadboard Mini Circuit Board is a reusable platform for building and testing electronic circuits without soldering. It allows quick modifications, making it ideal for students, hobbyists, and engineers to prototype designs.

Description

Introduction to Breadboard Mini Circuit Board

A Breadboard, also known as a solderless breadboard, provides a reusable platform for prototyping electronic circuits. Unlike stripboards that require soldering, breadboards support quick modifications without permanent connections. Students, hobbyists, and engineers often use Breadboard Mini Circuit Board for experimenting with circuit designs. While they don’t work well for high-frequency circuits, they remain a popular choice for testing simple and moderately complex setups.

Historical Background of Breadboard Mini Circuit Board

Originally, early electronic enthusiasts literally used wooden cutting boards to mount circuits by nailing wires and components directly. Over time, the concept evolved. Patents from the 1960s and 70s introduced spring-loaded holes and standardized spacings, especially the 0.1 inch (2.54 mm) layout. As a result, modern solderless breadboards became widely adopted for fast circuit experimentation.

Design and Structure

A typical Breadboard Mini Circuit Board includes bus strips for power and terminal strips for components. Moreover, internal metal clips connect groups of five holes, allowing seamless placement of ICs and discrete parts. Bus strips, often color-coded, distribute voltage and ground. Some models combine terminal and bus strips in a single unit, while others let users join them together modularly. Importantly, components like DIP ICs align perfectly with the board’s internal spacing.

Jump Wires and Usage of Breadboard Mini Circuit Board

Users connect components using jumper wires, typically 22 AWG. Whether pre-cut or hand-stripped, these wires form the circuit’s pathways. Breadboards are widely used in microcontroller-based projects, enabling users to test GPIO, I²C, or SPI connections with minimal setup. Furthermore, breadboards support small SoC (system-on-chip) PCBs for more complex tasks.

Limitations and Alternatives

Despite their versatility, breadboards suffer from parasitic capacitance, high resistance, and poor support for high-speed signals (above ~10 MHz). They also cannot handle surface-mount devices without adapters. Consequently, for large or precise projects, alternatives like PCBs, wire wrap, and stripboards are preferred. Still, breadboards remain essential for learning and quick prototyping.

Visit our website Ampflick for more products.

You can also visit our Instagram and Facebook for latest update.

Only logged in customers who have purchased this product may leave a review.

Reviews

There are no reviews yet.